Production activities

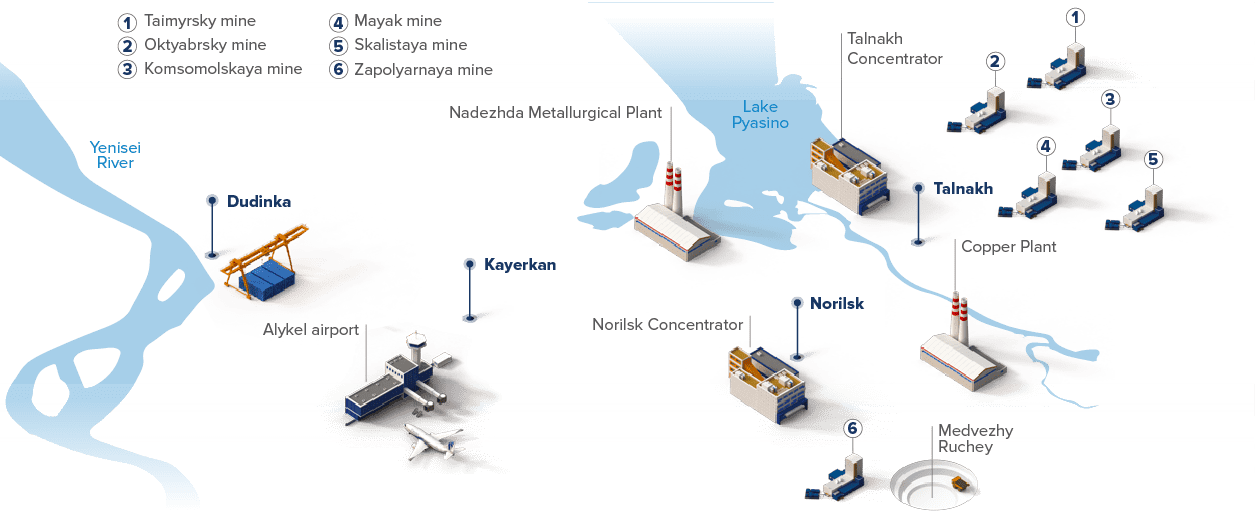

Taimyr Peninsula (Polar Division and Medvezhy Ruchey)

In 2H 2017, Nornickel established Medvezhy Ruchey, a subsidiary that operates part of the assets of Polar Division, including Zapolyarny mine, Norilsk Concentrator, tailings pit No. 1 and Lebyazhye tailing pit. The carve-out was done to create separate Talnakh and Medvezhy Ruchey sites with a view to ramping up the new unit’s capacities by raising investments.

Polar Division and Medvezhy Ruchey are the Group’s flagship subsidiaries featuring a full metals production cycle that embraces operations ranging from ore mining to the shipment of end products to customers. Operating the Company’s largest fields, they mine ca. 17 mtpa of ore. In 2017, Polar Division and Medvezhy Ruchey accounted for 77% and 35% of copper and PGM output, respectively.

They are located beyond the Arctic Circle on the Taimyr Peninsula in the north of the Krasnoyarsk Territory, Russia. The sites are linked to other regions by the Yenisey River, the Northern Sea Route and by air.

The Talnakhskoye and Oktyabrskoye Fields are developed by Taimyrsky, Oktyabrsky, Komsomolsky (including Komsomolskaya and Skalistaya mines) and Mayak mines. Ores are extracted through slicing and chamber mining with flowable backfilling.

The Norilsk-1 Field is developed by Zapolyarny mine through open-pit and underground mining. Underground mining is carried out through level caving using single-stage excavation and front ore passes.

| Field/mine | Mine type | OresHigh grade ores are characterised by a higher content of non-ferrous and precious metals; cupriferous ores are characterised by a higher copper content vs nickel; disseminated ores are characterised by a lower metal content. |

|---|---|---|

| Oktyabrskoye Field | copper-nickel sulphide | |

| Oktyabrsky mine | underground | high grade, cupriferous and disseminated |

| Taimyrsky mine | underground | high grade |

| Talnakhskoye Field | copper-nickel sulphide | |

| Komsomolsky mineIn 2010, the Talnakh Mining Administration was transformed into Komsomolsky mine consisting of Komsomolskaya, Skalistaya and Mayak mines. In 2015, Mayak mine was spun off from Komsomolsky mine (consisting of Komsomolskaya, Skalistaya and Mayak mines) to become an independent operation. Komsomolsky mine was left with Komsomolskaya and Skalistaya mines., including | ||

| Komsomolskaya mineKomsomolskaya mine is responsible for the development of the Talnakhskoye Field and the eastern part of the Oktyabrskoye Field. | underground | cupriferous and disseminated |

| Skalistaya mine | underground | high grade |

| Mayak mineIn 2013–2014, part of Komsomolsky mine. | underground | high grade and disseminated |

| Norilsk-1 Field | copper-nickel sulphide | |

| Zapolyarny mineIn 2010, the Norilsk-1 Mining Administration was transformed into Zapolyarny mine. Medvezhy Ruchey mine was integrated into Zapolyarny mine as Zapolyarny open pit. On 14 July 2017, Zapolyarny mine became a standalone unit of Medvezhy Ruchey., including | ||

| Zapolyarny open pit | open pit | disseminated |

| Zapolyarnaya mine | underground | disseminated |

| Ore type | 2015 | 2016 | 2017 |

|---|---|---|---|

| High grade | 6,541,541 | 6,191,831 | 6,593,208 |

| Cupriferous | 5,403,755 | 7,080,627 | 7,165,500 |

| Disseminated | 5,382,273 | 3,971,752 | 3,618,576 |

| TOTAL | 17,327,569 | 17,244,210 | 17,377,284 |

In 2017, Polar Division’s total ore output stood at 17.4 mt, up 133 kt, or 0.8% y-o-y. The production of high grade and cupriferous ores increased by 6.5% and 1.2% y-o-y, respectively, driven by the performance of Taimyrsky mine and Skalistaya mine demonstrating a 40% growth y-o-y. Cupriferous ore production was higher thanks to Oktyabrsky mine’s results. In 2017, disseminated ore production was down by 9% – primarily due to lower output at Zapolyarny mine. The change in the volumes of ore mined was in line with the annual production plan.

Concentration facilities

- Talnakh Concentrator

- Norilsk Concentrator (now part of Medvezhy Ruchey)

Talnakh Concentrator processes high grade and cupriferous ores from the Oktyabrskoye Field to produce nickel-pyrrhotite and copper concentrates and metal bearing products. The key processing stages include crushing, breaking, flotation and thickening.

Norilsk Concentrator processes cupriferous and all disseminated ores from the Talnakhskoye and Oktyabrskoye Fields and Copper Plant’s low grade ores to produce nickel and copper concentrates. The key processing stages include crushing, breaking, gravitation and flotation enrichment, and thickening.

Thickened concentrates are transported via a pipeline from Talnakh and Norilsk Concentrators to smelting facilities for further processing.

In 2017, Polar Division’s Production Association of Concentrators processed a total of 18 mt of feedstock (including high grade, cupriferous and disseminated ores).

In 1H 2017, Talnakh Concentrator operated against the backdrop of implementing and fine-tuning a new technology, moving on to reach the design capacity in 2H 2017 and beat the 2016 ores processing volume by 1.5 mt in the full year (10.0 mt vs 8.6 mt). Nickel recovered into collective flotation concentrate from ore processed increased by 2.2% y-o-y (81.7% vs 79.5%).

In 2017, volumes of ore processed at Norilsk Concentrator were 0.6 mt lower (7.5 mt vs 8.1 mt in 2016) – in line with the mining plan. Nickel recovered into collective concentrate was 0.8% higher (71.7% vs 70.9% in 2016). During the year, the facility processed significant volumes of Copper Plant’s low grade ores.

Talnakh Concentrator

Norilsk Concentrator

Smelting facilities

- Nadezhda Metallurgical Plant

- Copper Plant (CP)

- PGM Concentrator (part of Copper Plant)

Nadezhda Metallurgical Plant produces converter matte and elemental sulphur from the following:

- Talnakh Concentrator’s nickel-pyrrhotite concentrate and metal bearing products;

- Norilsk Concentrator’s nickel concentrate;

- pyrrhotite concentrate previously stored at Kayerkansky Open Pit Coal Mine (KUR-1).

| Metal | 2015 | 2016 | 2017 |

|---|---|---|---|

| Nickel, t | 96,916 | 50,860 | 0 |

| Copper, t | 292,632 | 280,347 | 306,859 |

| Palladium, koz | 1,935 | 1,703 | 956 |

| Platinum, koz | 488 | 449 | 259 |

Pyrrhotite concentrate from Talnakh Concentrator and stored pyrrhotite concentrate from Kayerkansky Open Pit Coal Mine is further leached in Hydrometallurgical Shop to produce steam cured sulphide concentrate. Concentrate from Talnakh Concentrator, steam cured sulphide concentrate and stored pyrrhotite concentrate from Kayerkansky Open Pit Coal Mine are delivered to the flash smelting furnaces. The matte is then blown into high grade converter matte.

Copper Plant processed all of the copper concentrate from Norilsk and Talnakh Concentrators, as well as third-party feedstock, to obtain copper cathodes, elemental sulphur and sulphuric acid for production needs of Polar Division.

PGM Concentrator (part of Copper Plant) recycles sludge from the tank-house to produce concentrates of precious metals and technical selenium.

Precious metals produced by Polar Division are refined at Krasnoyarsk Precious Metals Refinery under a tolling agreement.

At Polar Division, metals are produced from its own feedstock. Since Q4 2016, all nickel converter matte from Nadezhda Metallurgical Plant has been processed at Kola MMC due to the Nickel Plant shutdown.

Product offering:

- copper cathodes;

- nickel converter matte for Kola MMC;

- precious metal concentrate;

- commercial lump sulphur;

- technical selenium.

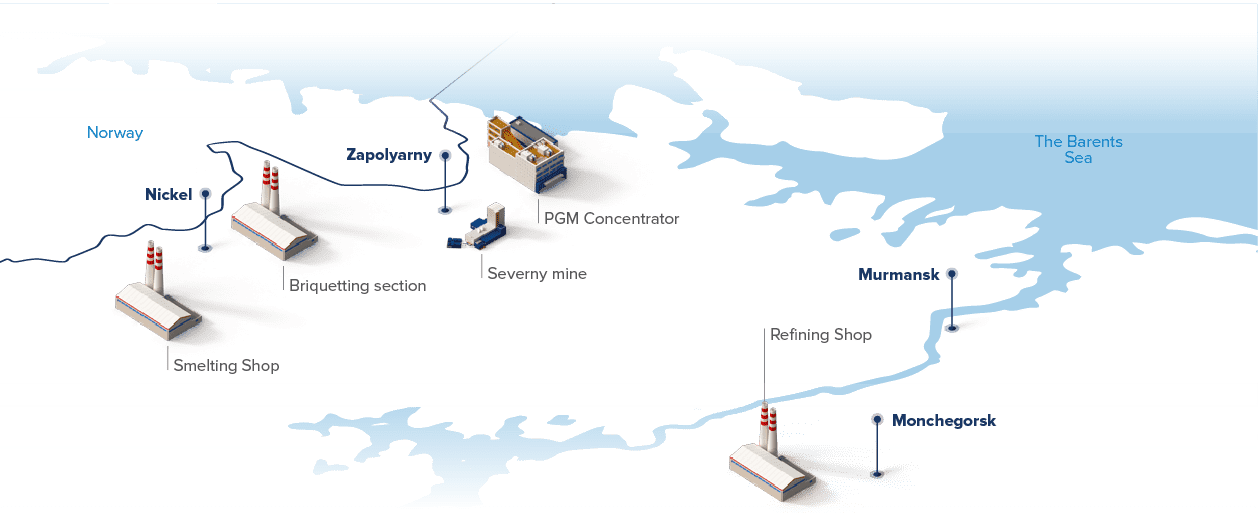

Kola Peninsula (Kola MMC)

Kola Mining and Metallurgical Company (Kola MMC) is Norilsk Nickel's 100% subsidiary and an important production asset.

Located on the Kola Peninsula in Russia's Murmansk Region, Kola MMC is fully integrated into the transport infrastructure of the Northwestern Federal District.

| Field / mine (section) | Mine type | Ores |

|---|---|---|

| Zhdanovskoye Field | Copper-nickel sulphide | |

| Severny underground section | Underground | Disseminated |

| Zapolyarnoye Field | Copper-nickel sulphide | |

| Severny underground section | Underground | Disseminated |

| Kotselvaara and Semiletka Fields | Copper-nickel sulphide | |

| Kaula-Kotselvaara mineIn December 2013, Kaula-Kotselvaara mine was merged with Severny mine and incorporated therein. | Underground | Disseminated |

| Ore type | 2015 | 2016 | 2017 |

|---|---|---|---|

| Disseminated | 7,962,226 | 7,615,518 | 7,643,224 |

Kola MMC is currently developing the Zhdanovskoye, Zapolyarnoye, Kotselvaara and Semiletka Fields.

Severny mine (including Kaula-Kotselvaara mine) produces disseminated sulphide ores containing nickel, copper and other saleable components. Severny mine leverages various ore mining methods:

- the Zhdanovskoye Field uses sublevel longwall caving with front ore passes, block caving (limited scope of application), and open-pit mining (at Yuzhny open pit) methods;

- the Kotselvaara and Semiletka Fields primarily use stoping from sublevel drifts and sublevel caving, as well as room-and-pillar short-hole and long-hole stoping (limited scope of application).

Kola MMC’s total ore output amounted to 7.6 mt, up 0.4% (28 kt) y-o-y owing to the development of flank deposits at the Zhdanovskoye Field.

The change in the volumes of ore mined was in line with the annual production plan.

Concentration facilities

- Zapolyarny Concentrator

The Concentrator produces briquetted copper-nickel concentrate. Nkomati concentrate also undergoes briquetting. Briquettes are delivered to the Smelting Shop to produce converter matte.

In 2017, Kola MMC's Concentrator processed 7,600 mt of ore, up 32 kt y-o-y.

In 2017, the rate of metals recovery in bulk concentrate was above the 2016 level due to a lower content of hard-to-process and talcose ores in the ore mixture.

Smelting facilities:

- Smelting Shop (Nickel)

- Briquetting section (Zapolyarny)

- PGM Concentrator (Monchegorsk)

- Refining Shop (Monchegorsk)

- Tank-Houses 1 and 2 (Monchegorsk)

In 2017, Kola MMC continued improving production processes and proceeded with the maintenance of key production equipment at its smelting facilities.

In Q1 2017, it commissioned a disposal facility for saline effluent from nickel refining operations at Tank-House 2. Tank-House 2 saw further implementation of the project for Nickel Electrowinning from Chlorine Dissolved Tube Furnace Nickel Powder with the Production Volume of 145 ktpa of Electrolytic Nickel.

Kola MMC’s refining facilities in Monchegorsk process converter matte from Nickel's Smelting Shop and Polar Division.

Precious metals produced by Kola MMC are refined at Krasnoyarsk Precious Metals Refinery under a tolling agreement.

In 2017, Kola MMC achieved a higher metal output compared to 2016. The growth was primarily driven by larger converter matte supplies from Polar Division after production reconfiguration.

Product offering:

- nickel cathodes;

- carbonyl nickel;

- saleable nickel concentrate;

- copper cathodes;

- electrolytic cobalt;

- cobalt concentrate;

- precious metal concentrates;

- sulphuric acid;

- crushed converter matte for Harjavalta;

- saleable copper concentrate.

| Metal | 2015 | 2016 | 2017 |

|---|---|---|---|

| Nickel, t | 125,100 | 131,235 | 157,396 |

| including from the Company's Russian feedstock | 123,335 | 126,937 | 155,110 |

| Copper, t | 63,075 | 70,272 | 80,781 |

| including from the Company's Russian feedstock | 60,134 | 63,542 | 78,586 |

| Palladium, koz | 671 | 851 | 1,782 |

| including from the Company's Russian feedstock | 640 | 815 | 1,731 |

| Platinum, koz | 134 | 173 | 401 |

| including from the Company's Russian feedstock | 122 | 159 | 385 |

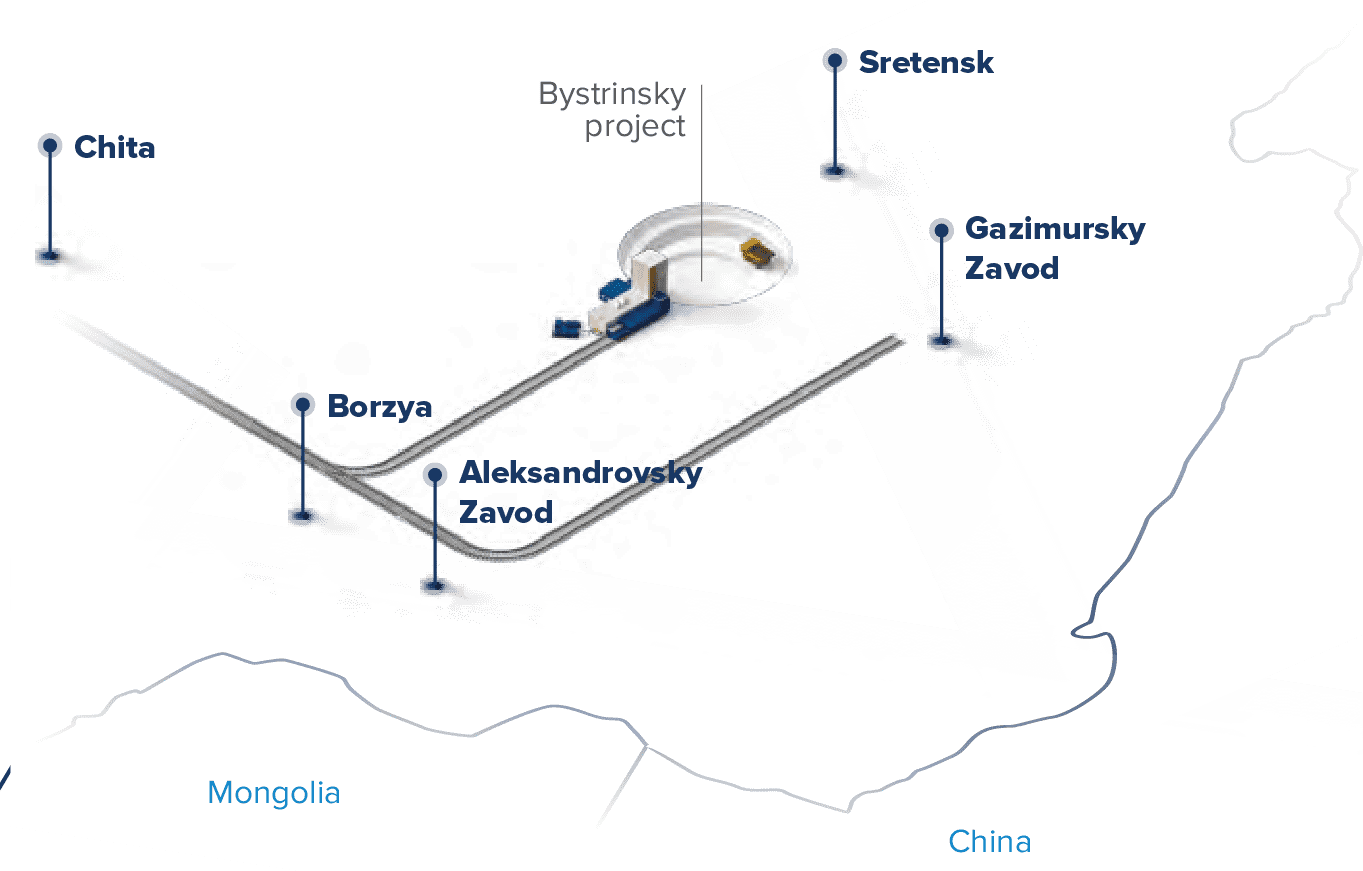

Zabaykalsky Krai (GRK Bystrinskoye)

GRK Bystrinskoye (Bystrinsky GOK) is the Company’s 50.01% subsidiary.

This new Nornickel project is the largest in the metals industry in Russia, as its operations include ore mining, concentration and shipment of end products to customers. The volume of ore mined and processed is expected to exceed 10.0 mtpa.

The construction of Bystrinsky GOK started in 2013. In October 2017, the Company embarked on the pre-commissioning phase. The facility is expected to switch to normal operation by the end of 2018 reaching its design capacity after 2021.

Bystrinsky GOK is located in the Gazimuro-Zavodsky District of Zabaykalsky Krai, south-east of Gazimursky Zavod in the Ildikan valley (350 km from Chita). The closest residential areas are Novoshirokinsky, 14 km north-east of the facility, and Gazimursky Zavod, a district capital 25 km to the north-west.

The Naryn – Gazimursky Zavod rail line was built to facilitate mining in the south-east of Zabaykalsky Krai. In 2012, the railway became operational, allowing traffic to Gazimursky Zavod.

| Field/mine | Mine type | Ores |

|---|---|---|

| Bystrinskoye Field | Gold-copper-iron | |

| Verkhneildikansky open-pit mine | Open pit | Gold-copper-iron |

| Bystrinsky-2 open-pit mine | Open pit | |

| Medny Chainik open pit mine | Open pit | |

| Yuzhno-Rodstvenny open pit mine | Open pit |

Bystrinsky GOK leverages the vast copper, gold and iron ore reserves of the Bystrinskoye Field.

Concentration facilities

- Concentrator

The construction began in 2015. The Concentrator is intended to process rich and cupriferous ores of the Bystrinskoye Field to produce copper, magnetite, and gold concentrates. The key processing stages include crushing, grinding, flotation, thickening, filtration and packaging.

The Concentrator is designed to have two separate processing streams. The first stream is now at the pre-commissioning stage. Its launch will enable the facility to reach 50% of its design capacity.

In 2018, the second stream will be commissioned for the Concentrator to unlock its full design capacity.

Copper concentrate is expected to be exported to China, while magnetite and gold concentrates will be delivered to the Company’s other facilities for further processing.

Product offering:

- copper concentrate;

- gold concentrate;

- magnetite concentrate;

- silver.

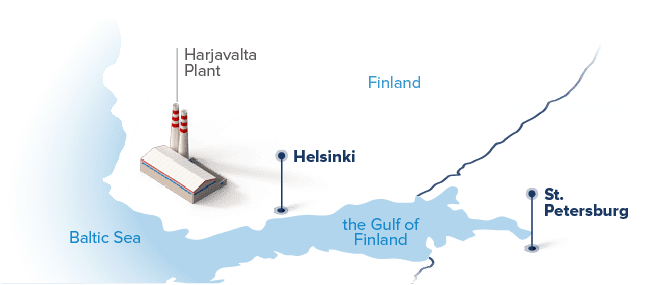

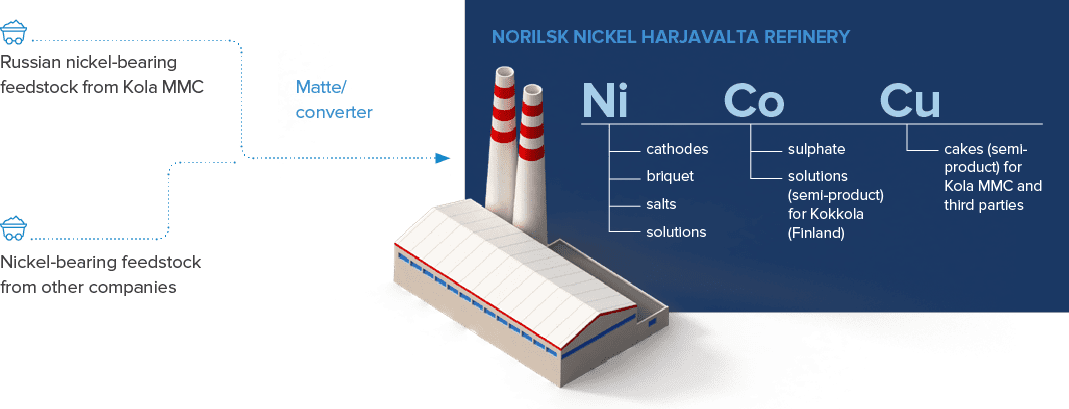

Finland (Norilsk Nickel Harjavalta)

Norilsk Nickel Harjavalta became part of the Group in 2007. It focuses on processing the Company's Russian feedstock and nickel-bearing raw materials sourced from third-party suppliers.

Norilsk Nickel Harjavalta has a total nickel processing capacity of 66 ktpa.

The facility uses sulphuric acid leaching, the world best-in-industry solution with the metal recovery rates of above 98%.

Founded in 1960, Harjavalta is the only nickel refinery in Finland and one of the largest similar facilities in Europe.

Process flowsheet of Norilsk Nickel Harjavalta

Nickel and copper recovery rates improved on the back of a drop in losses of nickel and copper with ferrous cakes.

In 2017, Norilsk Nickel Harjavalta produced 59.7 kt of saleable nickel, up 11% y-o-y. The growth was driven by the reconfiguration of refining facilities and increased nickel feedstock supplies from Kola MMC.

The third party sales of copper in copper cake totalled 13.4 kt, up 40% y-o-y. This was mainly due to the increased processing of Russian feedstock under the production reconfiguration programme.

The production of saleable palladium and platinum in copper cake dropped by 34% and 55% y-o-y, respectively, after imported feedstock had been replaced with Russian raw materials with a lower content of precious metals.

| Metal | 2015 | 2016 | 2017 |

| Saleable nickel, t | 43,479 | 53,654 | 59,716 |

| including from the Company's Russian feedstock | 424 | 19,012 | 55,021 |

| Copper in copper cake, t | 13,048 | 9,598 | 13,441 |

| including from the Company's Russian feedstock | 0 | 593 | 12,329 |

| Palladium in copper cake, koz | 78 | 64 | 42 |

| including from the Company's Russian feedstock | 0 | 8 | 35 |

| Platinum in copper cake, koz | 33 | 22 | 10 |

| including from the Company's Russian feedstock | 0 | 2 | 6 |

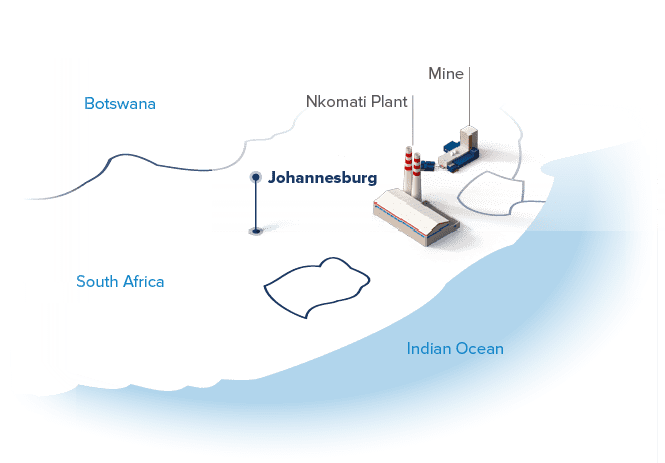

South Africa (Nkomati)

Nkomati is a 50/50 joint venture of the Norilsk Nickel Group and African Rainbow Minerals. Nkomati's performance is reflected in financial results using proportional consolidation according to our stake and not reflected in other totals.

Nkomati is located 300 km east of Johannesburg, Mpumalanga Province, South Africa.

It is the only South African company to produce nickel concentrate, which also contains copper, cobalt, chrome and PGM.

Nkomati has a substantial resource base represented by disseminated copper-nickel sulphide ores with several major ore bodies. The Main Mineral Zone (MMZ) is comprised of a solid sulphide ore body with a relatively high nickel content. The field also contains a Peridotite Chromite Mineralization Zone with a lower metal content vs MMZ and a relatively high chromium content.

The feedstock produced by open-pit and underground mining operations is processed at concentrators using sulphide floatation. The produced concentrates are then further processed at Kola MMC and third-party companies.

In 2017, total ore mined by Nkomati reached 3.5 mt (attributable to the Group’s 50% shareholding) with an average nickel content of 0.31%.

Concentration facilities

- MMZ Concentrator with installed capacity of 375 ktpm.

- PCMZ Concentrator with installed capacity of 250 ktpm.

The Norilsk Nickel Group accounted for 8.0 kt of nickel concentrate produced, which is lower than a year ago owing to reduced mining volumes and nickel content in ore processed.

| Metal | 2015 | 2016 | 2017 |

| Nickel, t | 11,350 | 8,486 | 8,006 |

| Copper, t | 5,301 | 4,007 | 4,504 |

| Palladium, koz | 53 | 40 | 46 |

| Platinum, koz | 20 | 15 | 20 |